Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

Fully automated handling and testing cell for surgical components by Pinger Robotic

Connect Four!

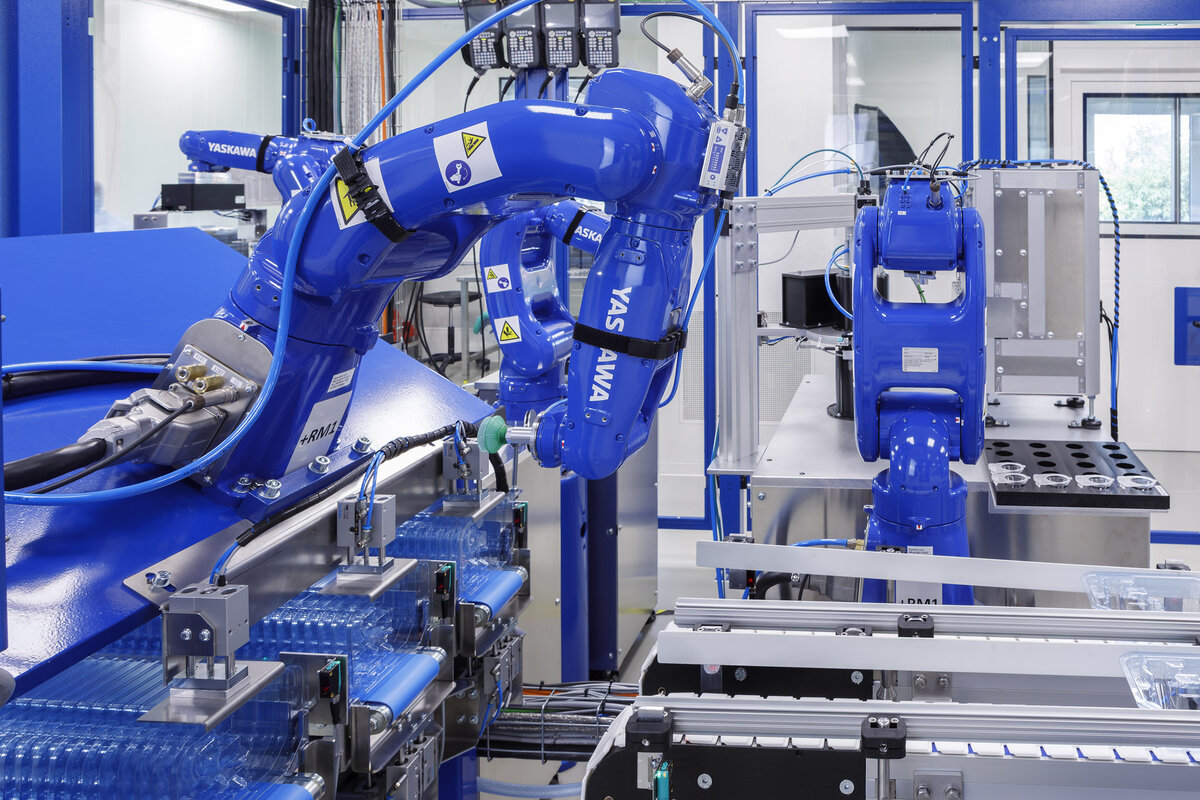

Initially, for Pinger Robotic, this order involved no more than automating the assembly of a camera-based testing system at medical technology specialist WaveLight. Further upstream and downstream handling steps were then added as the project progressed. The result is a handling and testing cell that is as complex as it is compact, in which a total of four MOTOMAN GP industrial robots from Yaskawa interact with high precision.

- Endüstriler

- Laboratuvar Otomasyonu Çözümlerimiz

- uygulamalar

- Material Handling

- müşteri

- Pinger Robotic GmbH

- Ürünler

- GP Serisi

- GP8 - GP Serisi

Just 30 years ago, laser eye surgery was new medical territory. Today, estimates [https://www.swr.de/leben/gesundheit/keine-brille-dank-augen-lasern-alles-rund-um-die-op-100.html] put the number at around 100,000 such procedures per year. WaveLight GmbH, headquartered in Erlangen (Germany), is benefitting from this rapid increase. As a global leader in this field, Alcon’s subsidiary develops and produces diagnostic and surgical technologies for refractive surgery. With success: Most recently, a new production hall was built and occupied at the Pressath (Germany) location, further increasing the medical technology specialist’s capacity.

The company also sees additional growth potential in the automation of further production steps. The focus is particularly on handling tasks which, due to their complexity, previously had to be carried out manually. Against this background, the experts at WaveLight also contacted robot manufacturer Yaskawa and its system partner Pinger Robotic GmbH, based in Polch in Rhineland-Palatinate.

Picture: The fully automated yet compact cell combines handling and testing tasks.

Task: Automated quality testing

Specifically, this request was about automating the quality testing of a component – more precisely: inserting it into the camera-based testing system and then removing a so-called applanation cone. The applanation cone is part of the WaveLight FS200 patient interface. This is a disposable medical product that connects the eye to the laser system during surgery. It consists of several components – an applanation cone, suction ring and hose system.

The task at Pinger Robotic initially consisted of only the automation of core processes, i.e. accurate removal of the applanation cones from the trays, insertion into the camera-based testing centre, removal after the inspection has been passed and precise pressing into the blister packaging – all of this within a specified cycle time.

“It has once again paid off that we as automation partners were involved at a very early stage,” says Jochem Pinger, Managing Director of Pinger Robotic, looking back on the last few months. This is because as the project progressed it became apparent that the upstream and downstream steps could also be usefully integrated into the solution – on the one hand feeding the trays and on the other hand separating the blisters, including the assembly of the conveyor technology for the onward transport of the tested and repackaged applanation cones within the factory.

The automation of these diverse handling processes made several aspects more difficult. Because they come from different sources, the plastic cones to be tested are present in different geometries. The delivery trays also vary in shape and layout, requiring flexible handling. Additionally, the entire process takes place in an environmentally controlled room. Compliance with strict hygiene standards prevents contamination of the products, and the components are then sterilized along with the blister packaging.

Picture: A total of four MOTOMAN GP industrial robots interact with high precision.

Solution: Plant concept with four robots

The result of the task-specific development work carried out by Jochem Pinger and his team is a fully automated handling and testing system with nevertheless compact dimensions. The heart of the system concept is a cell with a total of four industrial robots, which – like the popular strategy game “Connect Four!” – only develop their full strength when combined.

The four exactly synchronized robots take on different tasks along the process chain in parallel operation. The first one feeds the incoming trays from Zimmer using a flexible and automatically adjustable gripper. The second takes the applanation cones out of the trays and places them in the turntable of the camera testing station. The third again removes the applanation cones – after passing the quality check – from the turntable and places them in the blisters. The latter are finally separated by the fourth robot and placed on the conveyor belt. An automatically tested and packaged component leaves the system every six seconds.

But why robots and not, for example, conventional handling technology? Jochem Pinger has several convincing answers to this question: “Given the different shapes of the components and trays, conventional removal machines would not be flexible enough. And in any case, for classic assembly tasks, such as steps 2 and 3, there is no alternative to robots,” says the automation professional. “At most, an alternative could possibly have been found for the final handling of the blisters. However, the customer wanted a large intermediate buffer, so a robot proved to be the optimal solution here, too.”

Picture: A robot places the applanation cones, after passing the quality test, in the blisters.

MOTOMAN GP series: universally applicable

In the selection of robots the company opted for manufacturer Yaskawa. “We work well with Yaskawa and have always felt well advised. In addition, in this case the brand was also favoured by the customer,” says Jochem Pinger, justifying this step. Specifically, four MOTOMAN GP8s are now being used. “With a load capacity of 8 kilos, this model is exactly the right size for this system.”

The compact and extremely fast handling robots of the GP series (“GP” stands for “General Purpose”) were developed for particularly fast joining, packaging and general handling applications. Introduced as the fastest industrial robot in its class, the MOTOMAN GP8 is designed entirely in protection class IP67. Smooth surfaces also make cleaning easier. Although not explicitly designed to be hygienic (such as the MOTOMAN HD series), this GP robot is also very suitable for environmentally controlled areas like WaveLight.

Its sleek, curved design also allows the manipulator to delve deep into workspaces. All that is needed is a robot cable to connect the manipulator and control. The advantages of this solution are less wear and reduced space requirements. The costs of maintenance and spare parts storage are also reduced.

Picture: The minds behind the automation solution (from left): Jochem Pinger (Managing Director of Pinger Robotic) with Oliver Pfaff (Director of Manufacturing Operations) and Production Manager Hubert Witzl from WaveLight.

Proven recipe for success

The fully automated handling and testing cell with its four MOTOMAN robots has been successfully in operation at WaveLight since June 2025. The combination of powerful robotics with self-developed software solutions has once again proven to be Pinger Robotic’s recipe for success. And last but not least, individual elements of these complex systems can also be used profitably for other applications.

Author:

Florian Kohut, Key Account Manager Packaging Industry, Yaskawa Europe GmbH – Robotics Division, DE-Allershausen

Contact for readers’ enquiries:

Tel.: +49-8166-90-0

robotics@yaskawa.eu

www.yaskawa.de

Source for all pictures: Yaskawa Europe GmbH