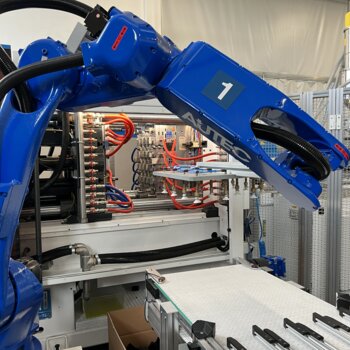

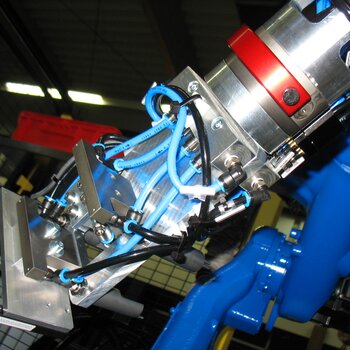

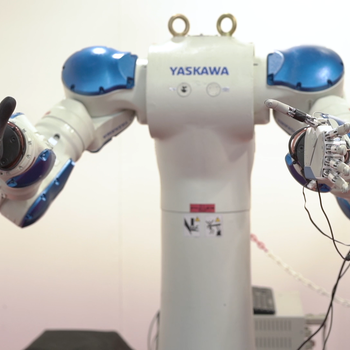

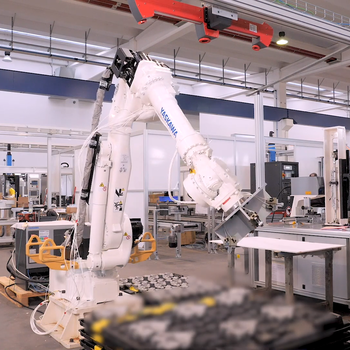

Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

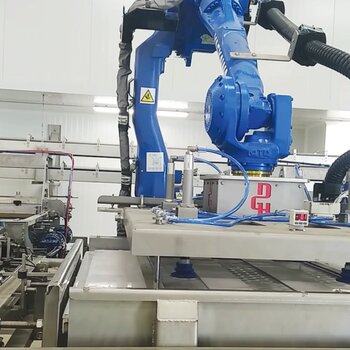

Material Handling

Kurumsal Sektörel Çözümler Uygulamaya Göre Material Handling

Ürünlere Genel Bakış

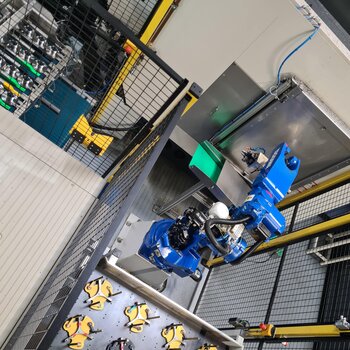

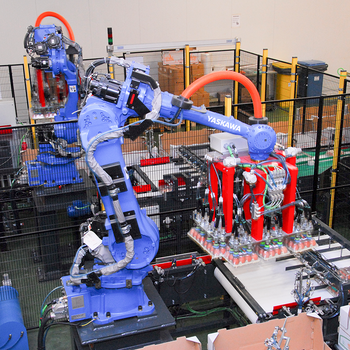

Material Handling with Motoman Robots

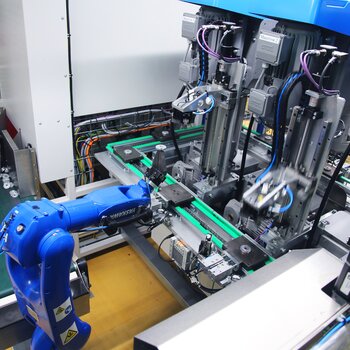

The term "Material Handling" is a helpless attempt to categorize the variety of possible applications for robots. You could include Assembly with all kinds of Fastening, Pick & Place, Packaging, Palletizing, Machine Tending and Press Tending or Bending in this category, but in our application overview pages we decided to give them separate pages. In fact, those mentioned applications are sequences of handling operations.

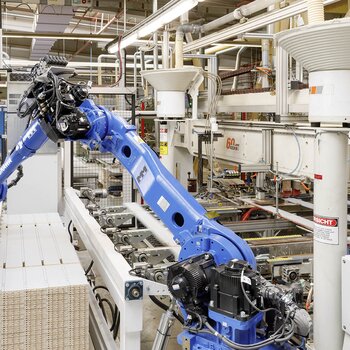

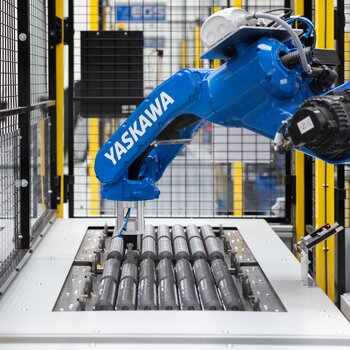

The benefits of robotic handling with GP series robots

Handling robots are used to move, feed or disconnect parts or tools to or from a specific location, or to transfer parts from one machine to another. Manufacturing companies around the world are integrating handling robots into their systems because of their speed, precision and cost effectiveness. Compared to manual handling, they also offer consistent quality standards and high repeat accuracy.

Industrial robots, many with vision technology or other equipment, relieve plant personnel of tedious and boring production line tasks, resulting in increased productivity and product quality.

The robots eliminate downtime, reduce labor costs and provide a high return on investment. They can also run year-round 24 hours a day.

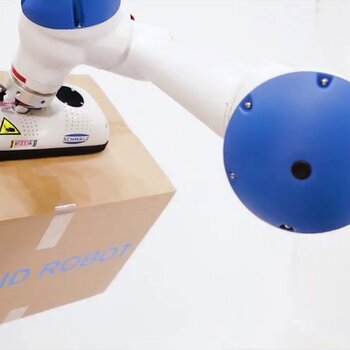

Mens - Robot - Samenwerken met HC-serie cobots

Wanneer het zinvol is om werkruimten tussen mensen en robots te delen (samenwerking of collaberatie), kunnen cobots uit de HC-serie een alternatief voor lean automatisering zijn. Ze zijn gecertificeerd voor gebruik in collaboratieve werkruimten. Hekken zijn niet nodig om de mens te beschermen.