Our industry-leading, high-speed industrial robots include high-payload, extended-reach, ultra-maneuverable seven-axis and unique 15-axis dual-arm robots.

Lemminkäinen Infra Oy

- Endüstriler

- Kimya ve Plastik Endüstrisi Çözümleri

- müşteri

- Lemminkäinen Infra Oy

For use in asphalt production and beyond

Inverter drives for harsh operating conditions

Inverter drives play an essential role in modern automation technology. This means that their capabilities are continually put to the test, often under difficult conditions. After all, unplanned downtime is not tolerable in virtually any production plant. This is just as true for mining, steel or cement production as it is for paper manufacturing, the automobile industry, the chemical industry or packaging technology. Numerous industrial sectors require inverter drives that not only offer functionality specific to the application, but also guarantee excellent reliability under difficult operating conditions and help to ensure reliable functioning of the entire plant. One company with such requirements is Lemminkäinen Infra Oy, Finland’s largest construction company.

Lemminkäinen Infra Oy is Finland’s largest construction company and a significant player throughout the Baltic region. Its activities include not only the construction and maintenance of road and rail networks, but also the production of the required raw materials. Between 2008 and 2009, for example, a state-of-the-art asphalt factory was built in Tuusula, Finland. It is now one of the three largest production facilities in Europe and produces approximately 500,000 tonnes of asphalt every year. The production volume per hour can reach up to 700 tonnes. Producing the required asphalt mixture – a combination of the bonding agent bitumen and various aggregates that must be adjusted for each individual application – is no easy task. Countless parameters must be considered in order to ensure, among other things, that the load capacity is suitable for the intended use of the final product. The basic production process, however, is easy enough to understand.

Drying, weighing, transporting, mixing

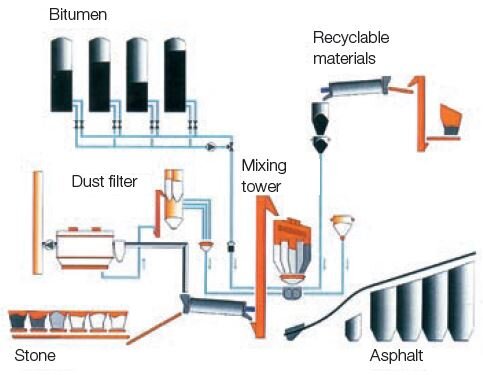

First, the aggregates are produced and then added to the dryer drum in pre-measured amounts. The moisture contained in the aggregate is then vaporised. The fine dust that is produced is separated by a dust removal system and can be weighed again later and added incrementally. The mineral compound, which has been pre-measured and heated according to the respective formulation, then leaves the dryer drum and enters the mixing tower. Here the measurement is refined and specific particle sizes are sifted out.

Once the desired composition of particle sizes has been achieved and weighed, the hot bitumen is injected into the mixing container and mixed with the mineral composite for a specified time. The fresh asphalt, which is approximately 150 to 180°C, is loaded directly onto trucks using silos. Recyclable materials are also processed in this way. Upon delivery, they are shredded, the moisture removed in a dryer, the results stored in a silo and then added to the mixing container in precise measurements according to the formulation.

More than 50 inverter drives in use

Drive technology clearly plays a major role in this automated manufacturing process. A total of 53 inverter drives with outputs between 2.2 and 160 kW need to operate reliably in the plant for the production process to run smoothly: 32 are located on the conveyor belt drives, eight on the blowers, five on the pumps and four on the 20-tonne dryer drums. Two more are used on the drives which transport the finished asphalt and two are used on the sieve machines. These inverters have to satisfy difficult requirements. During asphalt production, they must be able to cope with heavy, variable loads, in addition to fulfilling the stringent EMC guidelines so that they do not become a noise source for the control equipment. They also have to function unimpaired by the process-related operating conditions such as heat, cold or dust, so it was no great surprise that the Finnish plant operator chose the particularly robust inverter drives from Yaskawa. The inverters from the V1000 series (2.2 to 15 kW) and the A1000 series (22 to 160 kW) are impressive not only for their reliability and long service life, but also for their easy and convenient operation using the clearly designed LCD or LED control unit. Furthermore, the parameter structure is the same for all inverter drives. The principle of “if you know one, you know them all” therefore applies, which makes the technology very easy to use, especially when employing different inverter models. The Finns also know the value of good customer support. After all, it is important to receive fast and practical answers to your questions, not only during installation, but also during plant operation.

Reliable, convenient and practical

If the inverters need to be replaced, this can also be done without difficulty. While it is unlikely that the units will cause problems since they are designed to operate continuously for ten years (at 80% rated output), a replacement unit can be quickly installed in the unlikely case that this becomes necessary. This is made possible by the screwless removable control terminal and an integrated parameter backup. Data sets can therefore be quickly transferred to the new inverter, which leads to minimal downtimes. It does not stop there, however: the inverter drives used in Tuusula also have several further advantages which make them attractive for many other areas of application.

Both series of inverters are extremely compact in design and can therefore be installed “side by side” if needed, which of course saves installation space. Yet despite their comparatively small frame size, they achieve remarkable results: In heavy-duty mode, they can handle overloads of up to 150%. For applications that only require low overloads, the drive can be operated in normal-duty mode with up to 120% overload. This allows a smaller inverter drive to perform work that would normally require a larger drive. For controlled operation, the user can select between open-loop vector or V/f control.

With regards to communication capabilities, the inverters once again leave nothing to be desired since all conventional bus systems can be used to connect the inverters to a higher-level control network. The drive technology can therefore be incorporated into the user’s automation environment seamlessly. This opens up interesting possibilities in the areas of mechanical and plant engineering.